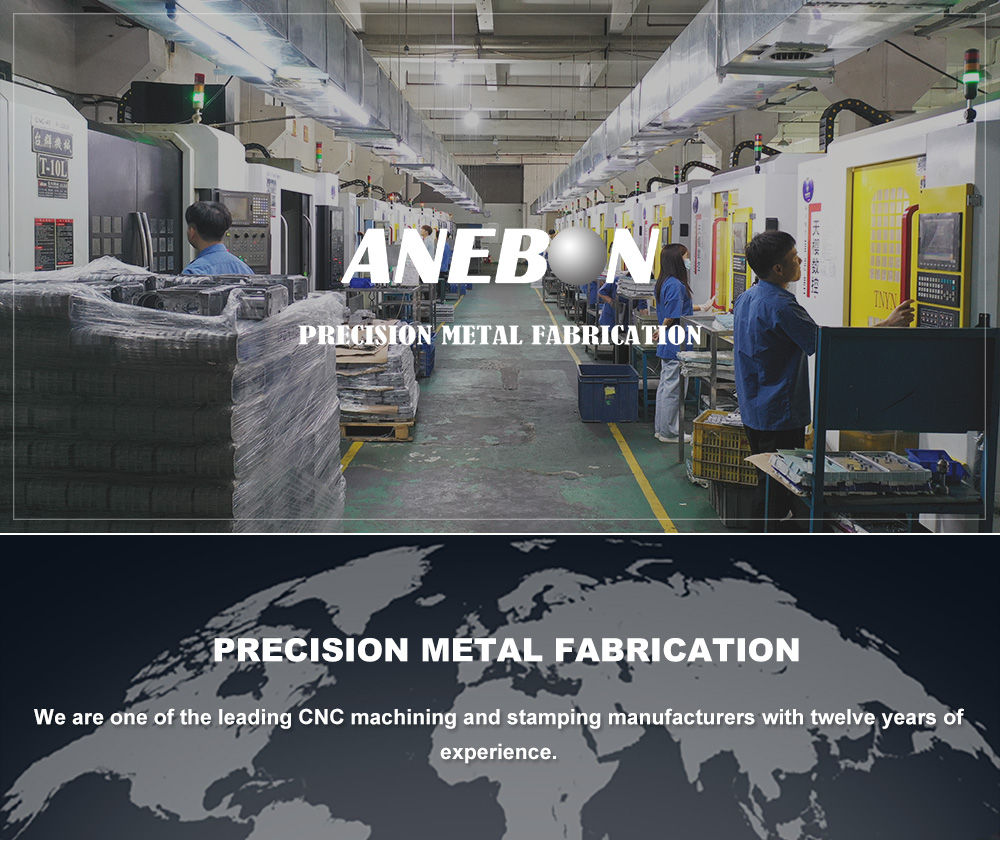

Die Casting Process

Hot chamber die casting, sometimes referred to as gooseneck die casting, is a molten, liquid, semi-liquid metal in a metal pool that fills the mold under pressure. At the beginning of the cycle, the piston of the machine is in a contracted state, at which point the molten metal can fill the neck of the goose. The air pressure or hydraulic piston squeezes the metal and fills it into the mold. The advantages of this system include a fast cycle (approximately 15 cycles per minute), easy automation, and the ability to melt metal.

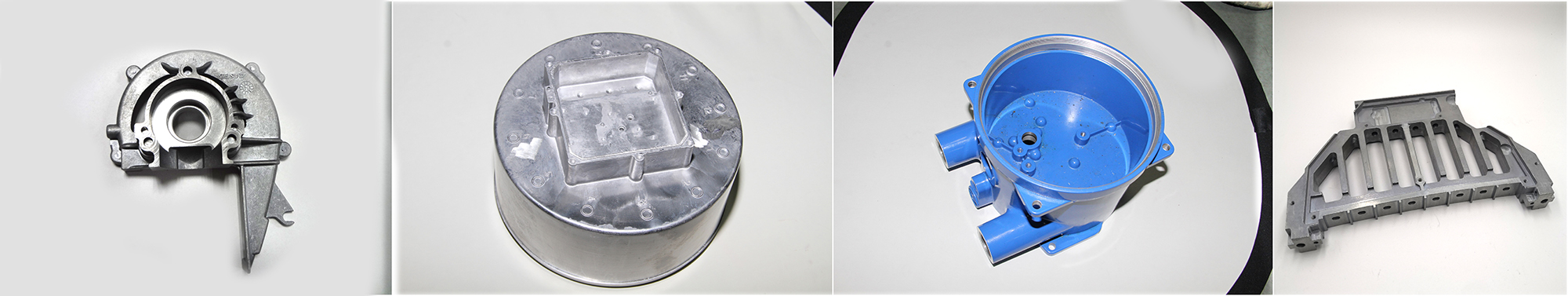

| Aluminium cnc milling | Die casting | Precision turned component |

| CNC milled aluminum | Casting parts | Precision turned components |

| CNC milling aluminum | Aluminum die casting parts | Turned parts |

.jpg)